Making a Beautiful Sugarcane Paper

Bagasse is the fibrous material left over after extracting juice from sugarcane. Once regarded as mere bio-waste, the preciousness of sugarcane bagasse as a renewable resource has come to light in recent years. Bagasse contains a significant amount of cellulose and is easy to cook, making it a great material for papermaking. But how exactly do you make a fine sugarcane paper? Let’s find out!

Kozo Studio's Sugarcane Paper

Material preparation

Following the sugar pressing, the sugarcane bagasse can be utilized in the production of paper. The agricultural residue of bagasse was gathered, dried under the sun for several days, and subsequently rinsed repeatedly with tap water.

Sugarcane Plants

Sugarcane bagasse

Pulping process

Making pulp involves four steps: cooking, washing, screening, and bleaching. We boil the bagasse in a mixture of 10% caustic soda for 30 minutes. Then rinse it multiple times with tap water. Next, we screen out the stiff part of the fiber and remove any unwanted impurities. The last process is optional and depends on whether you want to whiten the paper or not. If required, we use hydrogen peroxide, which is a total chlorine free bleaching agent. These chemicals are household items that can be easily accessed.

Sugarcane bagasse pulp is a kind of short fiber that's a bit like hardwood pulp, but not as tough and flexible. Here's the secret: if we mix in some long fibers pulp, we can use bagasse pulp to make really good papers. So, what's the best long fiber to use? Well, if you ask us, Kozo pulp is the way to go! You can experiment with the proportion of these two pulps to find the right mixture for you. You can use a blender for mixing the pulp. Fill the blender halfway. Pour warm water until the blender is full and blend for about one minute or until the mixture looks like a paste.

Papermaking process

Let’s break the papermaking process down into bullet points:

- Blend the pulp and water together in a vat or tub.

- Ensure that the pulp spreads evenly throughout the mixture.

- Stand the paper making frame mold upright and position it at the back of the tub.

- Make sure the side of the frame that will be used to scoop and shape the paper is facing towards you.

- Submerge the frame into the pulp mixture, ensuring complete and even coverage.

- Move the frame back and forth in the tub until the screen is filled evenly with pulp.

- Slowly lift the frame out of the tub, allowing excess water to drip off.

- Use a soft cloth to absorb the water from the bottom part of the frame.

- Leave the paper on the mold to dry completely. If it's a sunny day, take advantage of the sunlight!

And that’s it folk! Now you know how to make sugarcane paper at home!

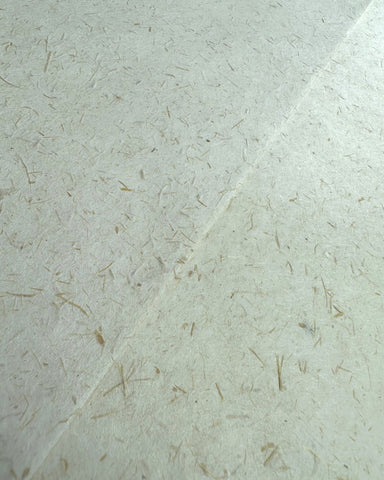

Kozo Studio’s Sugarcane Paper

With an annual production of over 3 million tons, Sukhothai province holds the position of being the third-largest sugarcane grower in the northern region of Thailand. We also have a few large sugar factories around the province. In other words, we have an unlimited supply of bagasse.

Through the utilization of bagasse residue, we actively promote environmental sustainability and contribute to a reduced carbon footprint. Most importantly, we craft exceptional and distinctive paper that excels in various artistic endeavors!